Browse Challenging Terrain with Self-confidence: Komatsu Undercarriage Parts Selection Overview

Browse Challenging Terrain with Self-confidence: Komatsu Undercarriage Parts Selection Overview

Blog Article

Boost Efficiency With Undercarriage Parts and Its Uses

Comprehending the detailed components that comprise the undercarriage of heavy equipment is essential for firms intending to enhance their functional efficiency. From track footwear to idlers and gears, undercarriage parts play a crucial function in the efficiency and durability of tools. The calculated utilization of these components can bring about significant enhancements in performance and expense savings. Let's explore just how organizations can harness the power of undercarriage components to enhance their operations and drive success in an affordable market.

Value of Undercarriage Parts

Regular upkeep and prompt replacement of undercarriage parts are vital to avoid expensive downtime and take full advantage of performance. Damaged undercarriage parts can result in minimized traction, boosted gas intake, and accelerated endure various other components of the machinery. By spending in high-grade undercarriage components and sticking to a stringent maintenance schedule, operators can optimize the performance of their hefty equipment and extend its life span.

Typical Kinds Of Undercarriage Components

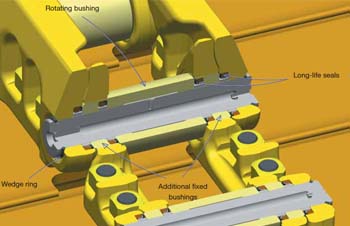

Essential components vital for the reliable procedure of heavy machinery, undercarriage parts play a crucial duty in ensuring ideal performance and longevity of the equipment. Some common kinds of undercarriage components consist of track chains, track footwear, rollers, idlers, sprockets, and track frames. Track chains are in charge of transmitting the equipment's weight and giving grip, while track footwear sustain the machine's weight and safeguard the track chain from wear. Rollers assist in assisting the track and improving its durability, while idlers assist control the track tension and lower use on the track system. Sprockets involve with the track web links and give the driving pressure for the device's movement. Track structures offer as the main framework supporting all the undercarriage elements. Comprehending the feature and importance of these usual undercarriage parts is essential for preserving hefty equipment in optimum working problem, lowering downtime, and optimizing performance on work websites. Normal evaluation, upkeep, and prompt replacement of these parts are crucial consider guaranteeing the overall effectiveness of hefty tools.

Advantages of Regular Upkeep

Enhancing functional efficiency and lengthening tools lifespan, normal upkeep of undercarriage parts is critical for taking full advantage of heavy machinery performance. By sticking to a structured upkeep schedule, drivers can protect against pricey breakdowns and decrease downtime. Routine inspections and maintenance of undercarriage elements such as tracks, sprockets, idlers, and rollers not only make certain smooth operation but likewise add to general safety on task sites.

Enhancing Equipment Performance

Additionally, picking her comment is here the best undercarriage components for certain operating problems is crucial. Variables such as the kind of surface, work, and environmental problems need to be taken into account when choosing undercarriage elements. Using top quality components that are created to hold up against the needs of the job can boost total equipment efficiency and longevity.

Moreover, maintaining undercarriage parts well-lubricated and clean is vital for smooth procedure. Dirt, particles, and absence of lubrication can create early wear and tear on elements, causing minimized efficiency and possible failures. Normal cleansing and lubrication regimens can help protect against these concerns and ensure consistent tools efficiency.

Economical Solutions for Services

To enhance undercarriage parts effectively and make certain lasting devices performance, organizations have to focus on affordable remedies that line up with their functional requirements and budget restraints. Investing in top notch undercarriage components can lead to considerable financial savings over time by reducing downtime, upkeep expenses, and the risk of unforeseen equipment failings. One affordable remedy for services is to implement an aggressive maintenance routine that consists of normal assessments, lubrication, and prompt replacement of damaged undercarriage elements. By recognizing and attending to potential problems at an early stage, businesses can stop costly fixings and prolong the lifespan of their tools.

In addition, services can discover different undercarriage components such as aftermarket parts that satisfy industry criteria and specs at a reduced price than OEM components. By meticulously reviewing their choices and partnering with reputable suppliers, organizations can successfully manage their undercarriage component expenses without endangering on performance or reliability.

Verdict

In conclusion, undercarriage parts play an essential duty in enhancing devices efficiency and productivity. It is clear that undercarriage parts are crucial elements for services looking to enhance efficiency and keep their equipment in optimum condition.

From track shoes to gears and you could try these out idlers, undercarriage parts play an essential function in the efficiency and longevity of site here devices.The importance of undercarriage components in hefty equipment can not be overstated, as they are essential elements that considerably influence the overall performance and long life of the tools.Vital elements crucial for the efficient operation of heavy machinery, undercarriage parts play a vital role in making certain ideal efficiency and longevity of the tools.Enhancing operational efficiency and extending devices life expectancy, regular maintenance of undercarriage parts is critical for taking full advantage of hefty machinery performance. In addition, organizations can explore alternative undercarriage parts such as aftermarket components that satisfy industry standards and specifications at a reduced price than OEM components.

Report this page